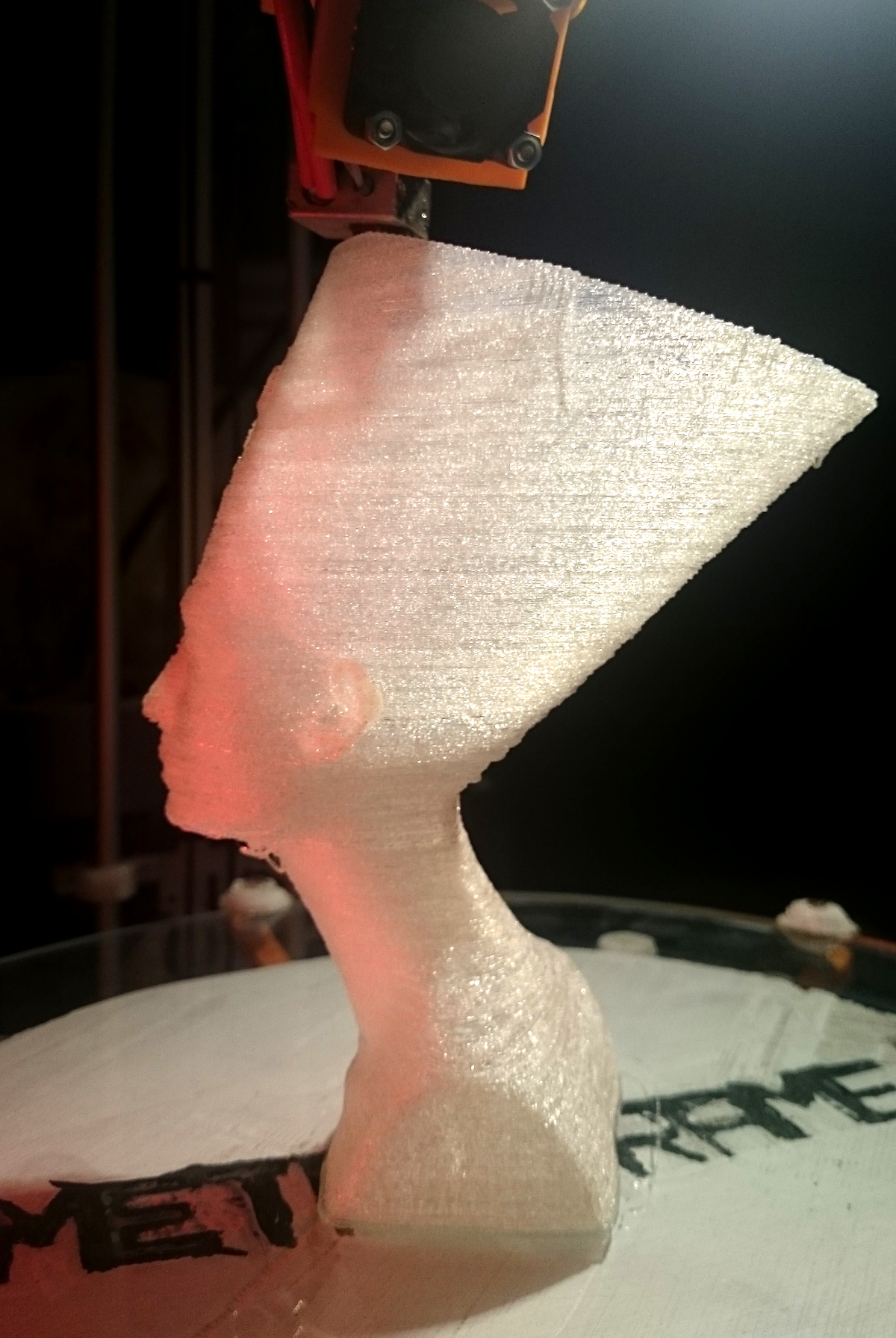

Saw this beautiful piece of art from over 3.3 k years. For sure thingiverse already had few versions of it so i downloaded files and went for it.

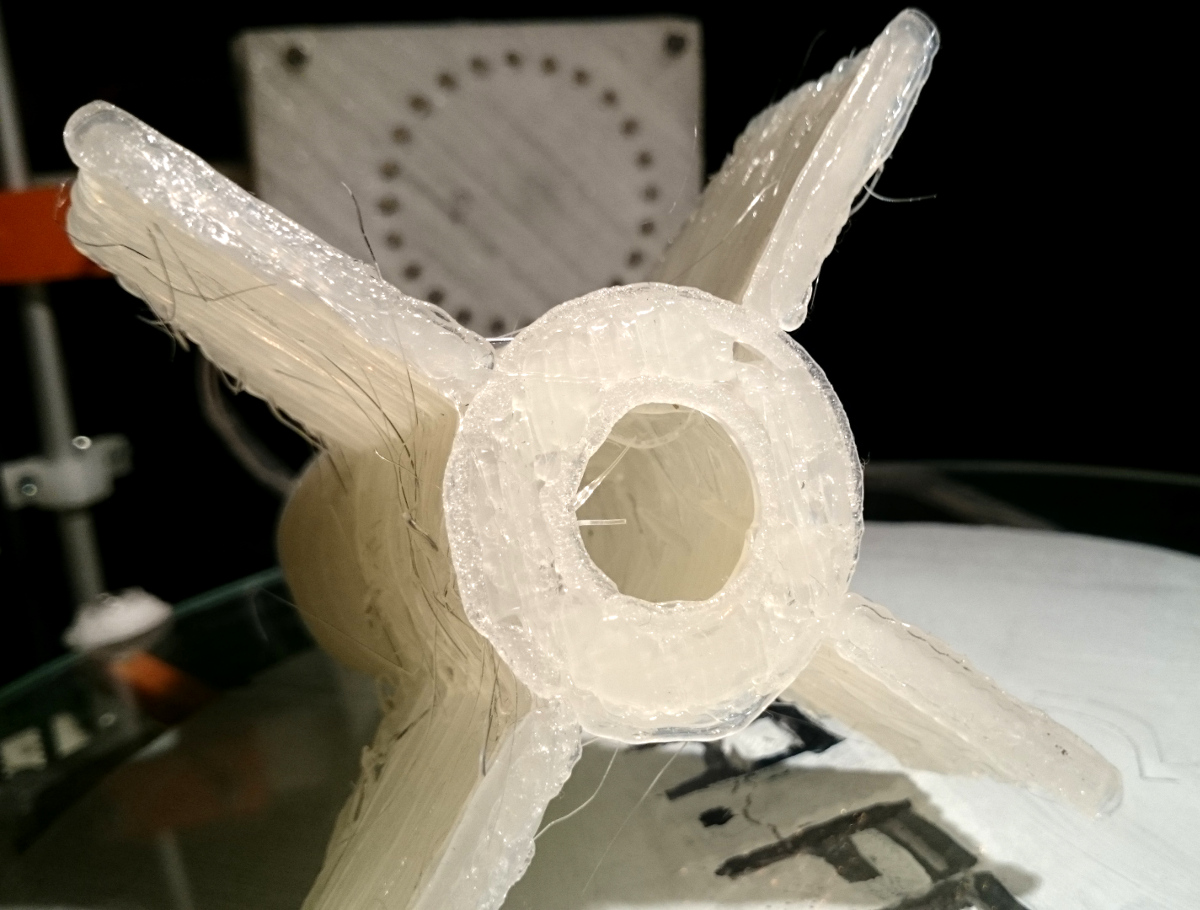

this was also thin wall first calibration run so i dont mind some imperfections, mtf.white recently got 1.3 mechanical upgrade so speed is still testish…

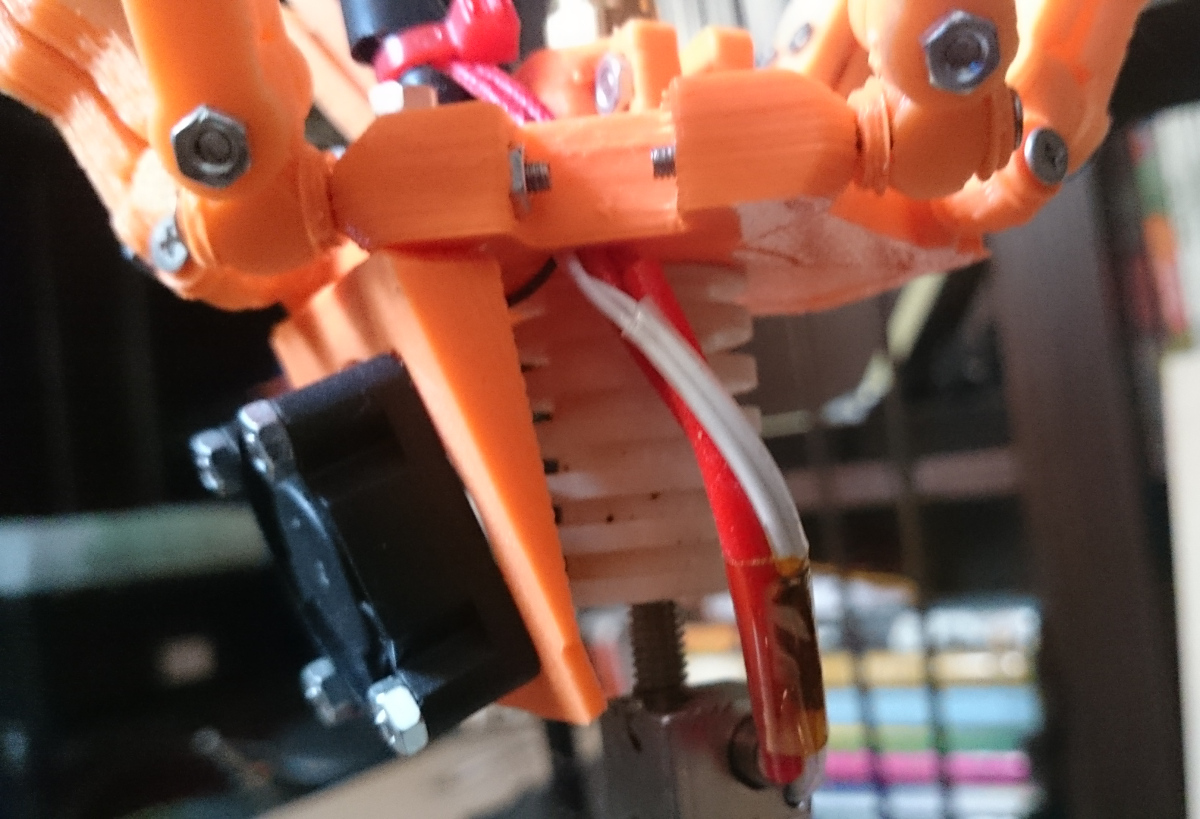

This was printed at 50% size since it is huge, i think xl will be able to pull it off in 1/1 but we shall see about that. Here is meta.frame white in action.

Whole print considering speed and early machine status took nice 6 hours, some problems were caused by me not checking how thin these walls really are so with minor tweeks i think we can do this much better.

Here is final product front

also side view

So, what needs to be changed? A bit more on extrusion ratio, bit lover temperature and higher speed will probably do the trick.

next time remember than when printing 0.4 nozzle always check your wall thickness.