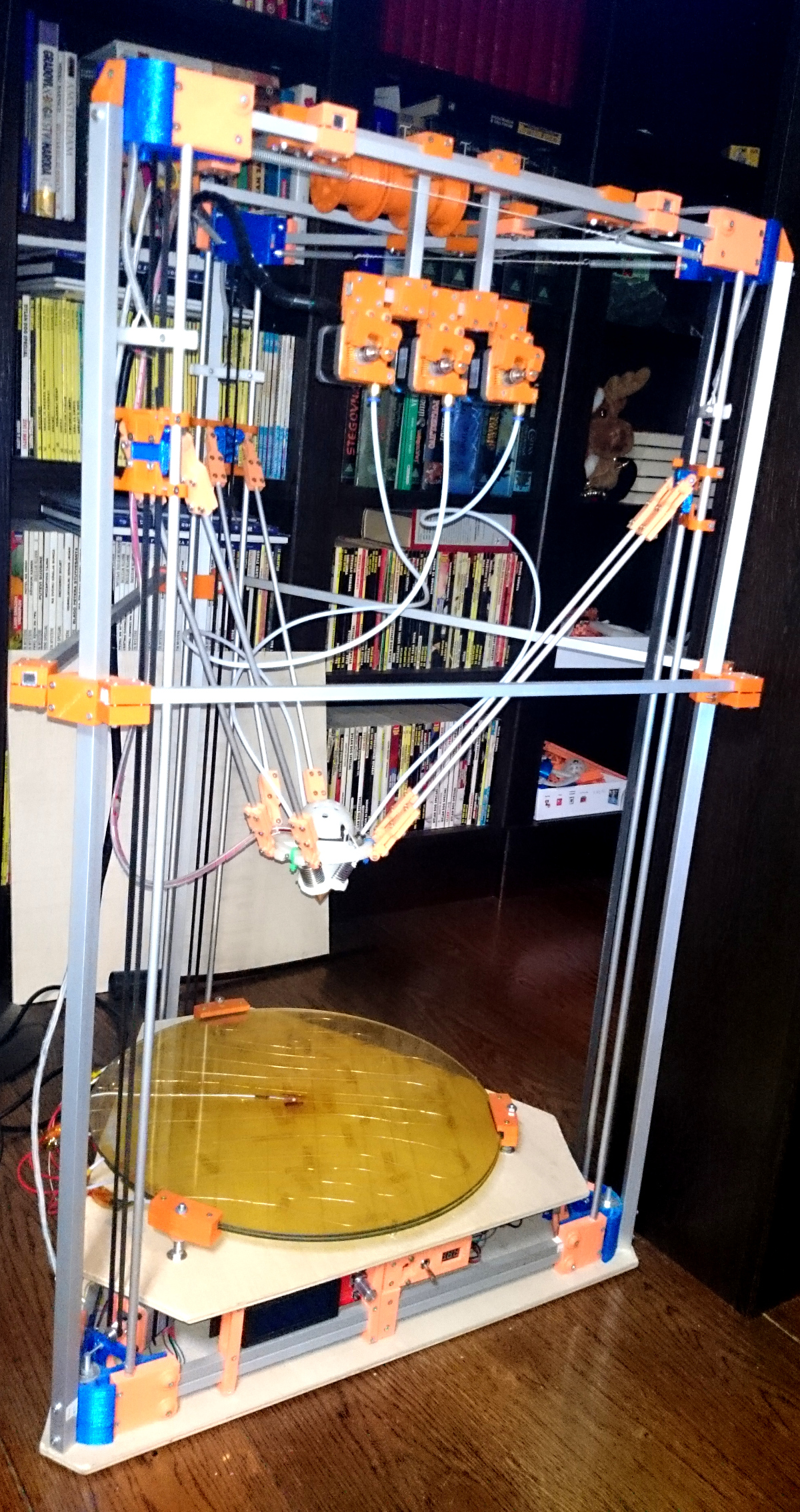

Ok, mechanical and movement segment of this metaframe.xl upgrade is pretty much complete. Firmwire is still in progress but i will keep you posted. First lets see full blown two major segments of this upgrade.

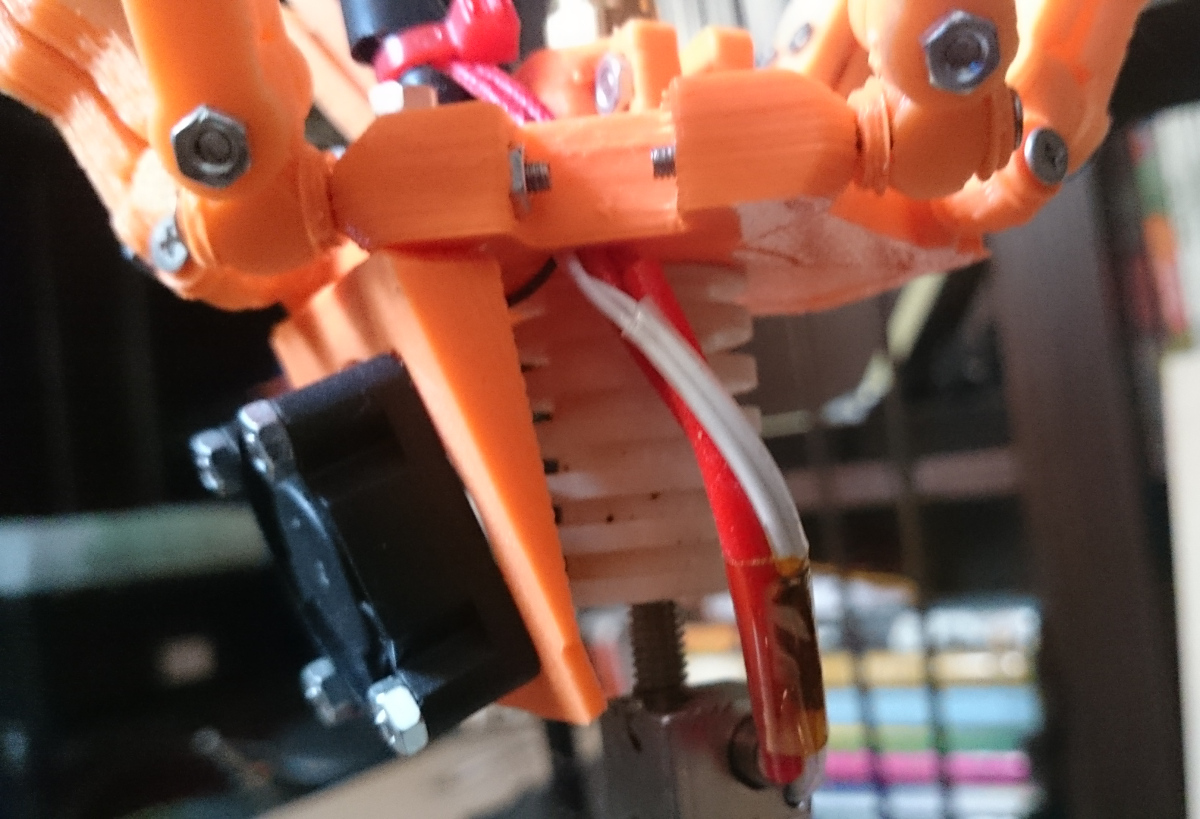

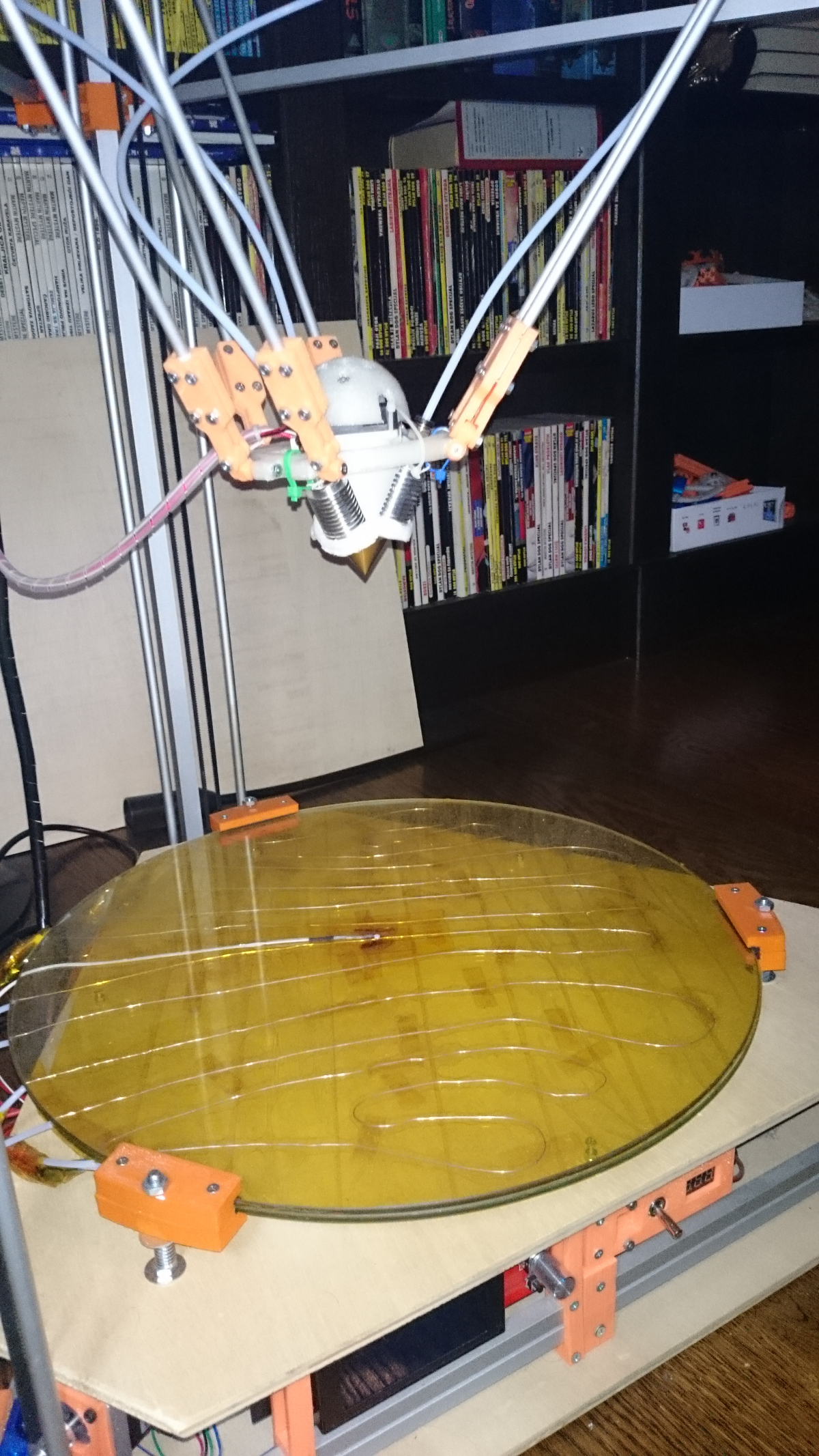

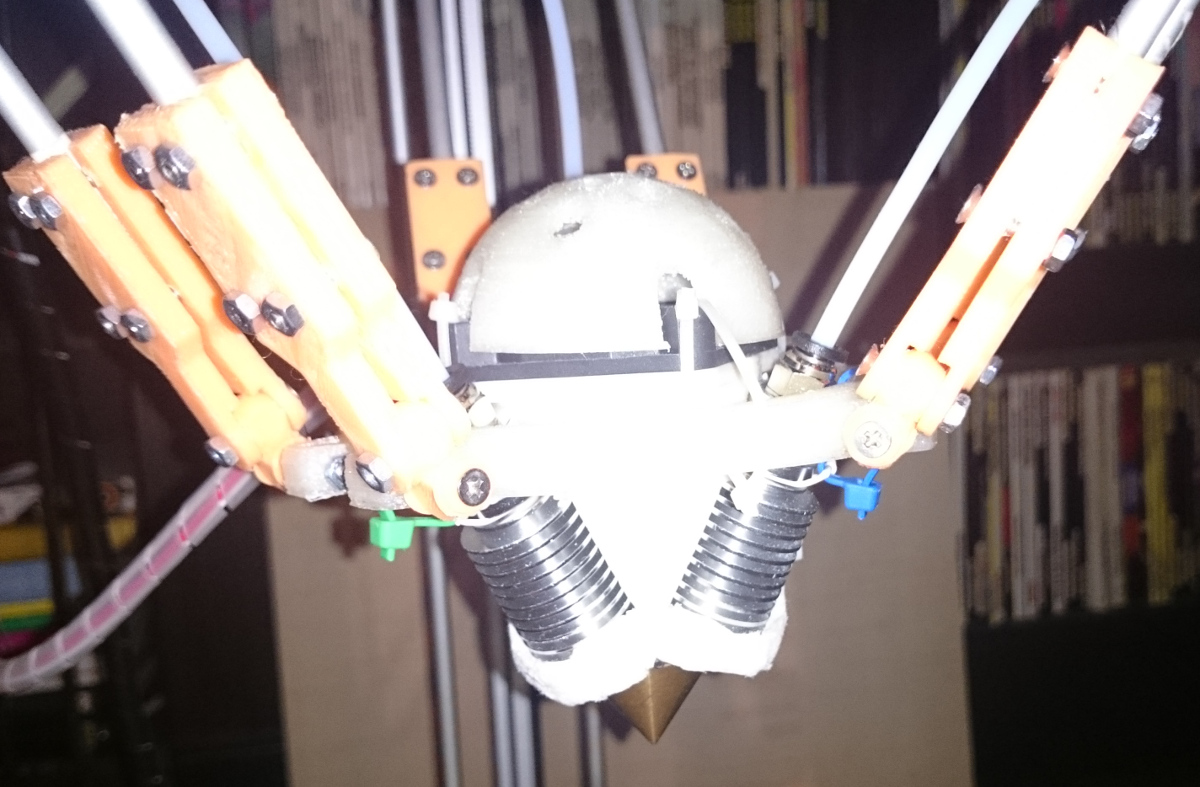

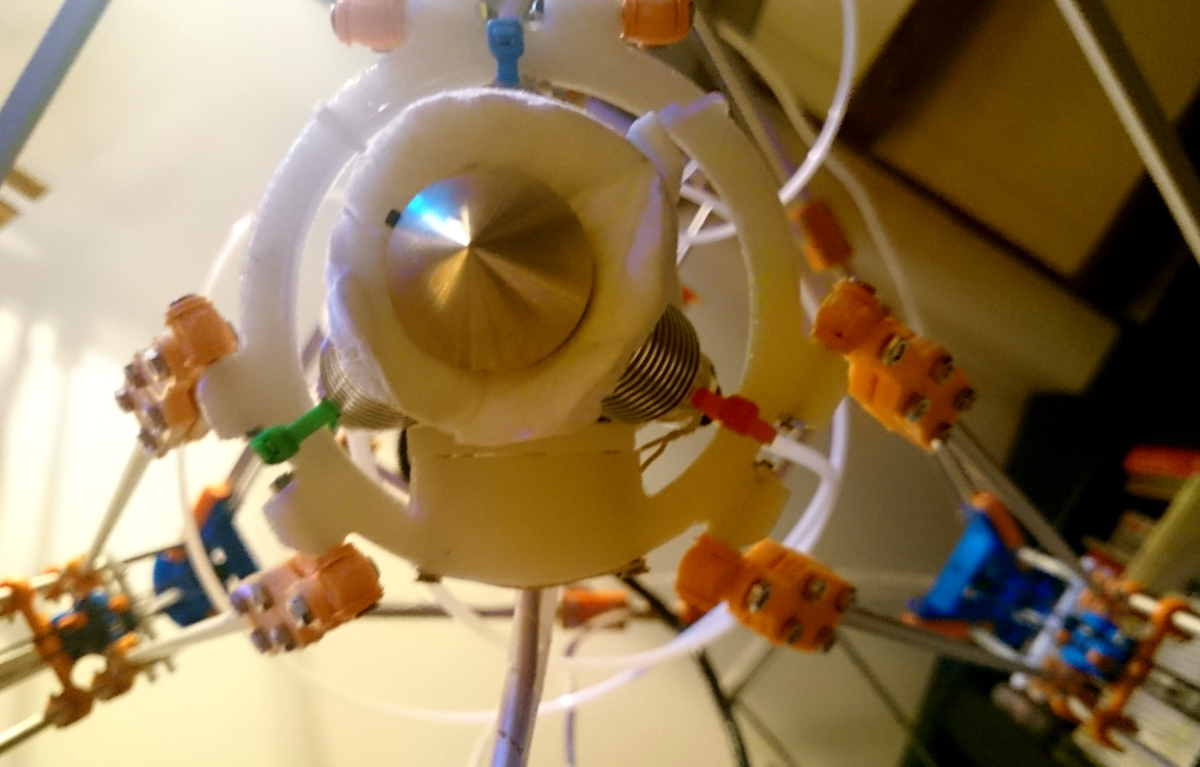

Print heated surface has grown to 42 cm diameter and is made of two melted toughened glass segments with nich wire on kapton tape. Also visible here are diamond hot end with custom adapter to accept default heat shield which comes with diamond. Print bed has easy leveling in three points and thic whole configuration is made for three 1.75mm filaments of your choice.

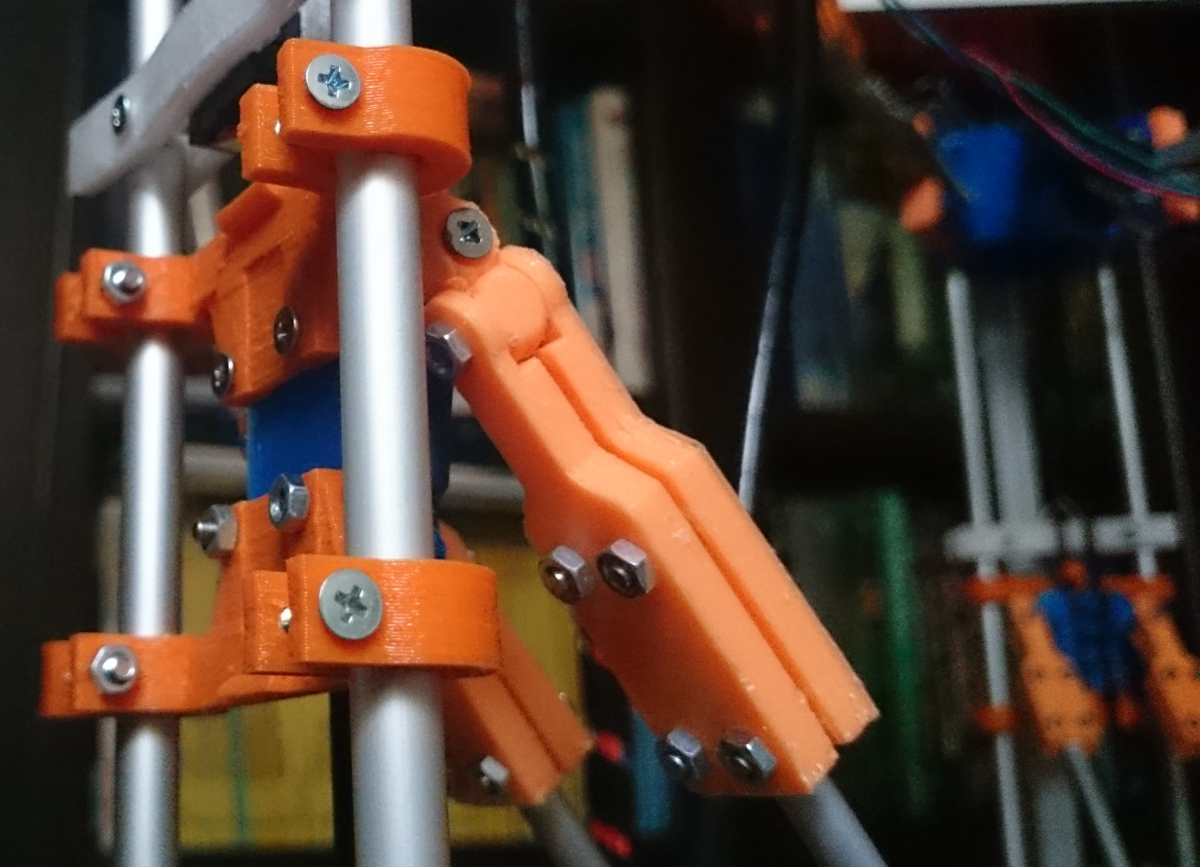

Also horizontal beam tension is added and it dampens all of movement of top side. It had to be done since we added two more kilograms of spools and also motors for triple extrusion. Whole actuator hot end is much more stable and leveled than with any extrude combination i used before.

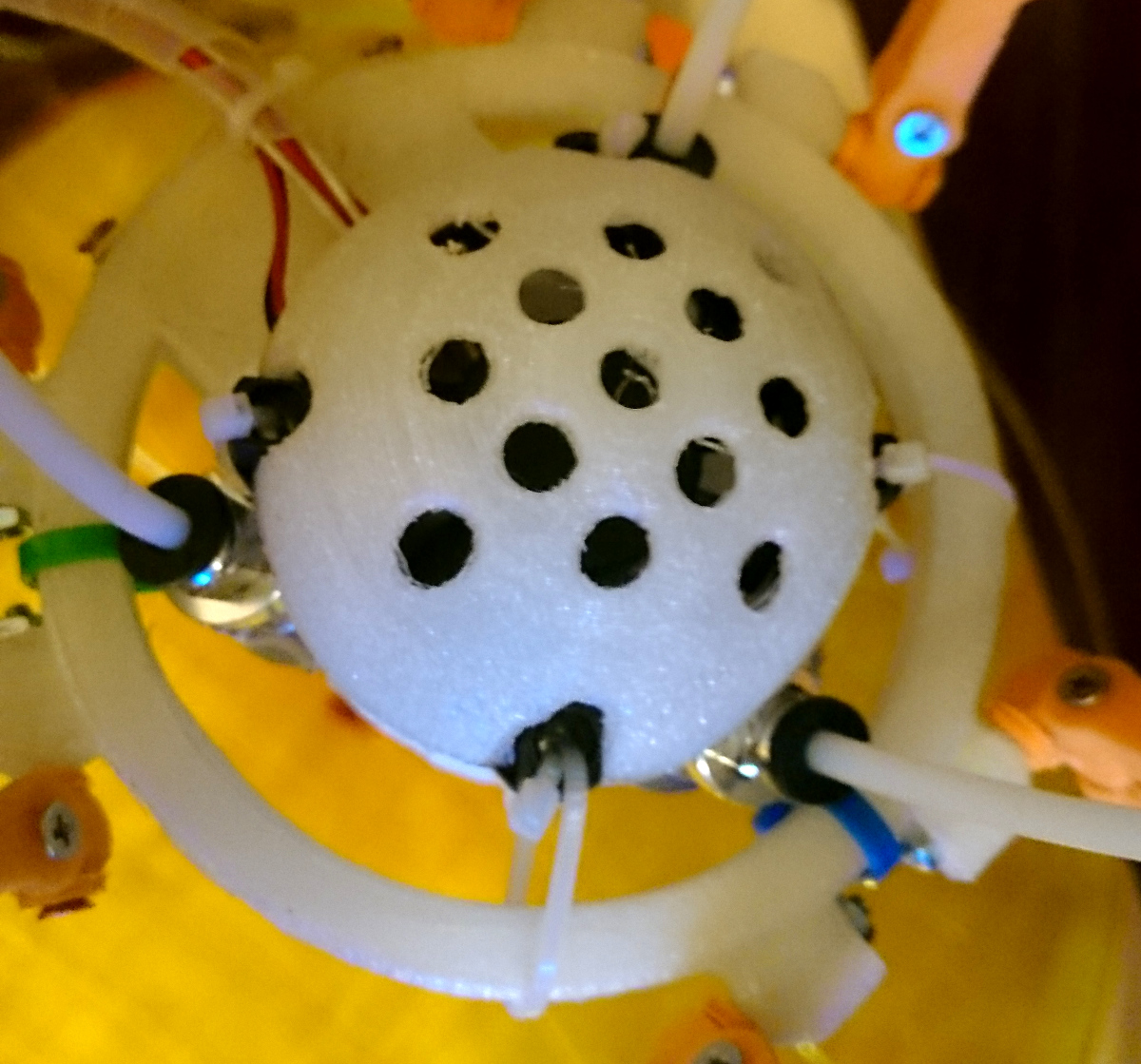

So this is top view and this space thingy is actually placeholder for filter since ventilation is vertical so lots of dust and plastic particles find their way into vents. So this was mechanical part, movement and extrusion is done using mega2560 / ramps 1.4 / extruder expander combination and all is left to do is some firmwire thingies to mix colors or support PVA material. Will keep you posted.