Two main material selections when dealing with everyday 3d printing using layer deposition technique are shorthand ABS and PLA. Broadly speaking both materials are thermoplastic but in essence are completely different beasts.

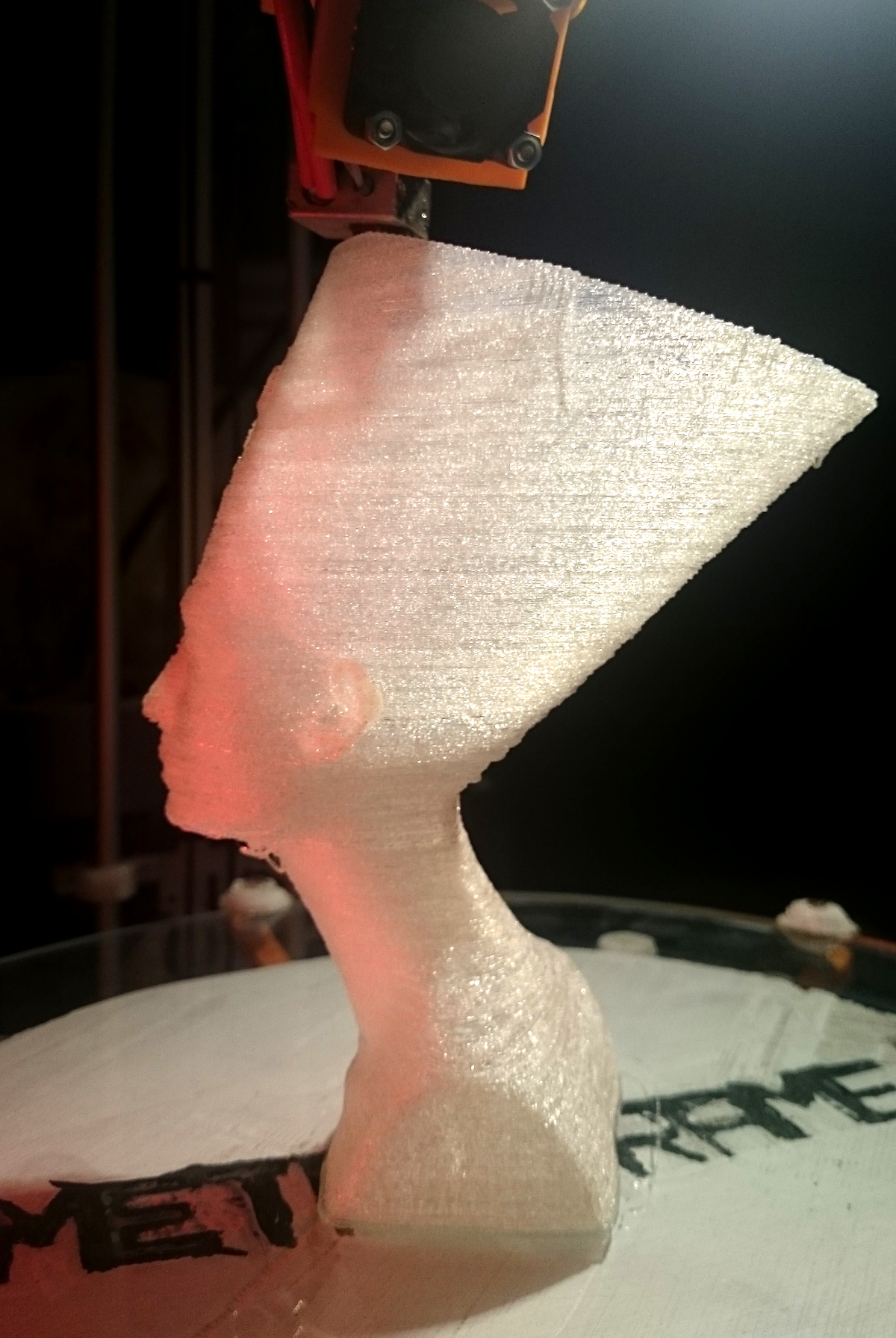

Polylactic acid or polylactide (PLA, Poly)

Biodegradable thermoplastic aliphatic polyester derived from renewable resources, such as corn starch, tapioca roots, chips or starch, or sugarcane. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. The name “polylactic acid” does not comply with IUPAC standard nomenclature, and is potentially ambiguous or confusing, because PLA is not a polyacid (polyelectrolyte), but rather a polyester.

Biodegradable thermoplastic aliphatic polyester derived from renewable resources, such as corn starch, tapioca roots, chips or starch, or sugarcane. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. The name “polylactic acid” does not comply with IUPAC standard nomenclature, and is potentially ambiguous or confusing, because PLA is not a polyacid (polyelectrolyte), but rather a polyester.

biodegradable thermoplastic aliphatic polyester PLA requires 185°C minimum temperature for print and 50°C min. temp. for heated print bed but can be printed without heated option.

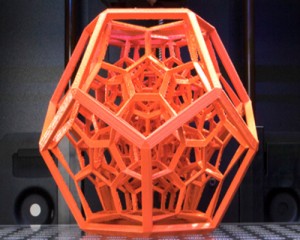

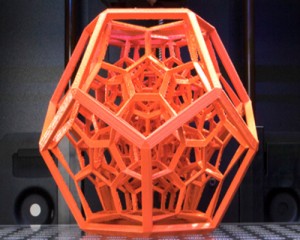

Acrylonitrile butadiene styrene (ABS)

ABS (chem. (C8H8)x· (C4H6)y·(C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15 to 35% acrylonitrile, 5 to 30% butadiene and 40 to 60% styrene.

ABS (chem. (C8H8)x· (C4H6)y·(C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15 to 35% acrylonitrile, 5 to 30% butadiene and 40 to 60% styrene.

amorphus thermoplastic acrylonite butadiene styrene ABS requires 225°C minimum temperature for print and 110°C min. temp. for heated print bed.

Meaning of this?

Having used now extensively both materials for long period of time on multiple machines and from different material manufacturers i can say PLA is way to go.

I still use ABS in some production scenarios but for prototyping and everyday usage PLA is more economical, ecological, to be more precise, 100% more biodegradable than ABS. First temperatures, PLA has much wider spectrum of temperatures that can be used so it is easier to find sweet spot for every spool but at generally lower temperatures than ABS. This leads to much more durable hot end parts and also less heat lost and power used. Also heated bed can sit at 65-70°C with PLA vs 125°C with ABS.

For sticking to print bed with PLA i use just fresh water vs acetone-abs slug when printing with ABS. Less time in wait to reach printing temperature is also significant advantage.

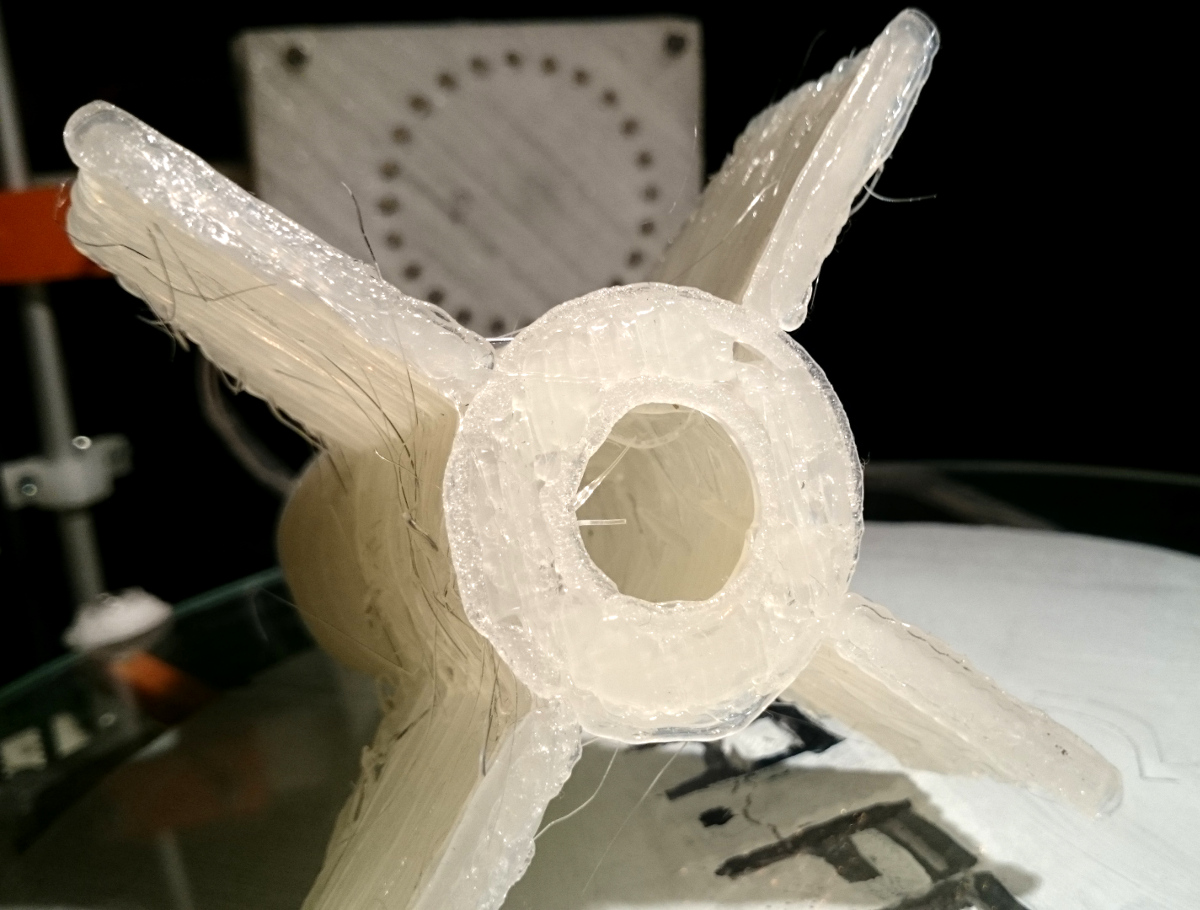

There are some cons also, PLA has lower melting temperature so for some applications ABS is better, also ABS is somewhat harder, tougher and more rigid when printed than PLA. PLA is somewhat more flexible and slippery so in some cases this is advantage and in some this is problematic.

Thermoplastic wars, the conclusion!

Thermoplastic wars, the conclusion!

There are tons of materials, vendors, colors to choose from and also everyday there is new material to start with and generally speaking it is very case related to say which is best, but somehow i always have some PLA available, just in case! I keep PLA rolls in storage box with lots of dehumidifier substances like rice or silica bags.

PLA is more ecological, completely harmless when printing and also completely biodegradable after, it is reusable, less power required and for me easier to work with. Machines also tend to last longer and if one can use 0.3 or wider nozzle to avoid clogging problem just be smart and use PLA.

Biodegradable thermoplastic aliphatic polyester derived from renewable resources, such as corn starch, tapioca roots, chips or starch, or sugarcane. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. The name “polylactic acid” does not comply with IUPAC standard nomenclature, and is potentially ambiguous or confusing, because PLA is not a polyacid (polyelectrolyte), but rather a polyester.

Biodegradable thermoplastic aliphatic polyester derived from renewable resources, such as corn starch, tapioca roots, chips or starch, or sugarcane. In 2010, PLA had the second highest consumption volume of any bioplastic of the world. The name “polylactic acid” does not comply with IUPAC standard nomenclature, and is potentially ambiguous or confusing, because PLA is not a polyacid (polyelectrolyte), but rather a polyester. ABS (chem. (C8H8)x· (C4H6)y·(C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15 to 35% acrylonitrile, 5 to 30% butadiene and 40 to 60% styrene.

ABS (chem. (C8H8)x· (C4H6)y·(C3H3N)z) is a common thermoplastic polymer. Its glass transition temperature is approximately 105 °C (221 °F). ABS is amorphous and therefore has no true melting point. ABS is a terpolymer made by polymerizing styrene and acrylonitrile in the presence of polybutadiene. The proportions can vary from 15 to 35% acrylonitrile, 5 to 30% butadiene and 40 to 60% styrene. Thermoplastic wars, the conclusion!

Thermoplastic wars, the conclusion!